Australian Hardwood Exterior Cladding is renowned for its robustness, natural beauty, and suitability for various climates. Sourced from native Australian trees like Jarrah, Spotted Gum, Blackbutt, and Ironbark, these hardwoods are prized for their durability and resistance to weathering.

H3 treated timber cladding to update the look of your home. Available in a range of colours, you are only limited by your imagination.

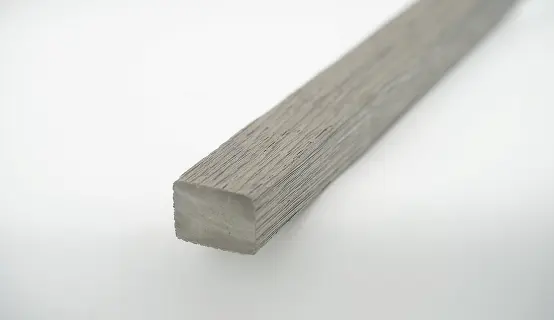

IronAsh H3 Cladding – IronAsh is a strong, durable cladding that has H3 treatment for a longer-lasting and better timber to protect your home.

Spotted Gum Cladding – The most sought-after cladding on the market, Spotted Gum is both beautiful and durable. Use as a feature to lift a home or space, or on an entire build. Either way, you’ll be the envy of your neighbours.

Ironbark Cladding – With rich browns and reds, Ironbark is great for cooler climates where warmth is needed. Finishing with oil or traditional varnishes will lift up the tones and keep the finish fresh for longer. Perfect for features around the home, south-facing walls, and where a darker colour is desired.

Silvertop Ash Cladding – With easy installation and a beautiful appearance, Silvertop Ash is a stunning timber that will only get better with age. If you like the classic weatherboard with the silvery colour then this cladding is for you.

Cavity door pockets to suit 2040mm and 2340mm refer to components used in the installation of cavity sliding doors, which are doors that slide into a concealed pocket within the wall rather than swinging open like traditional hinged doors.

The cavity door pockets are specified to accommodate doors of these heights, ensuring that the pocket is appropriately sized to fit the door and allow for smooth operation.

We have the solution you need, whether you want a sliding door that blends into the background quietly or a feature opening to make a statement.

Cement Australia offers a range of bagged cementitious products designed for various construction, building, and DIY (do-it-yourself) projects. Here are some of the typical bagged products offered by Cement Australia:

General Purpose Cement: This is a versatile cement suitable for a wide range of applications such as concrete, mortar, rendering, and DIY projects.

Builders Cement: Builders cement is a blended cement that typically contains higher proportions of clinker compared to general-purpose cement.

Rapid Set Concrete: This product is a premixed concrete blend designed to set rapidly when mixed with water.

High-Strength Concrete: High-strength concrete mixes are formulated to achieve higher compressive strength compared to standard concrete mixes.

Mortar Mix: Mortar mix is a blend of cement, sand, and additives designed for laying bricks, blocks, and stone in masonry construction.

Sand and Cement Mix: This product combines cement with graded sand to create a pre-mixed mortar suitable for general-purpose applications such as patching, rendering, and bricklaying.

Concrete Mix: Concrete mix is a pre-blended mixture of cement, sand, and aggregate (stones or gravel) that only requires the addition of water.

Hydrated Lime: Hydrated lime is often used in conjunction with cement and sand to create lime mortars or lime renders.

Off-White Cement: Off-white cement is a specialty cement that has a lighter color compared to standard grey cement.

Cement sheet products refer to building materials made primarily from cement, often combined with other materials like cellulose fibres, silica, and additives to enhance specific properties. These products are widely used in construction for their durability, fire resistance, and versatility. Here are some common types of cement sheet products:

Timber cladding refers to the use of timber or wood materials to cover the exterior walls of buildings. It serves both functional and aesthetic purposes in construction. It can be made from various types of wood, including softwoods like pine or cedar, or hardwoods like oak or teak.

The primary functions of timber cladding include providing weather resistance and thermal insulation to buildings, as well as enhancing the visual appeal of the exterior. It can be installed in different profiles and styles, such as horizontal or vertical boards, shingles, or panels, allowing for a range of architectural designs and finishes.

Baltic Pine Weatherboards

Dressed Primed H3 Treated Pine boards

Spotted Gum Shiplap Cladding

Silvertop Ash Shiplap Cladding

Blackbutt Shiplap Cladding

Ironash H3 timber Cladding

Thermory Cladding Range

CSR Plasterboard

The team at Paines Hardware & Timber hold stock of:

2400 x 1200

3000 x 1200

Wet Area 10mm RE – 2400 x 1200

We can order in for bulk orders and other products. Please contact us on 03 9435 2555 to discuss your requirements.

Gyprock and Australian Campaign (AMCL), a marketing agency for Australian building and construction manufacturers, have partnered to promote Australian products. Gyprock was the first to introduce paper-faced wallboards in Australia in 1947. This revolutionised the building industry. Gyprock is still a leader in innovation today, and continues to influence trends within the commercial, architectural, and home design space.

CSR Gyprock, Australia’s largest manufacturer of gypsum-based products, such as plasterboard, cornice and compounds, is also a leading supplier of adhesives, specialty materials, and finishing materials.

Gyprock offers a wide range of products and systems that are high-performance and meet the needs of construction industries in terms of fire, acoustic, and thermal performance.

Gyprock operates Gyprock Trade ™ centres and endorses Gyprock Specialist distributors outlets throughout the country to complement its strong retail presence at major hardware and building materials retail outlets. These outlets are geared towards the trade and offer everything from boards, cornices, compounds, tapes and tools to accessories.

Product Description

Gyprock’s range includes a variety of plasterboards, cornices, adhesives, specialty plasters, and finishing materials.

The majority of Gyprock’s products are made in Australia. A select range is sourced from top manufacturers around the globe to provide the best possible solutions for architects, designers and builders.

Gyprock is manufactured in state-of-the art manufacturing facilities owned by the company. Each facility performs regular tests under a Quality Management System that complies with ISO 9001/2000, ensuring you can specify our products and use them with confidence. Learn more about Gyprock’s manufacturing process.

Gyprock, the Australian term for “plasterboard”, has been around since 1947. The introduction of paper-faced wallboards revolutionised the construction industry, allowing lightweight building methods to be used.

Looking for timber supplies in Melbourne? Look no further than Paines.

Dressed hardwood” refers to hardwood timber that has been processed to achieve a smooth and uniform finish on all four sides through a planing or machining process. Here are the key characteristics and uses of dressed hardwoods:

Internal and external doors serve distinct purposes in building design, each tailored to specific functional and aesthetic requirements.

Internal Doors: Internal doors are primarily used within the interior of buildings to delineate spaces, provide privacy, and enhance sound insulation between rooms. They come in various styles, materials, and designs to complement the overall interior decor. Common materials for internal doors include wood (such as oak, pine, or mahogany), composite materials, and sometimes glass panels for a more open feel or to allow light transmission between rooms.

External Doors: External doors, also known as entry doors or exterior doors, are designed to provide security, weather protection, and aesthetic appeal for the main entry points of buildings. They are constructed to withstand outdoor elements such as rain, wind, and temperature fluctuations. External doors are often thicker and more robust than internal ones, commonly made from solid wood (such as oak or mahogany), fibreglass, steel, or aluminium. These materials offer durability, security features (such as reinforced cores and sturdy locks), and insulation properties to maintain energy efficiency within the building. External doors may feature decorative elements, glass panels for natural light, and weatherstripping to prevent drafts and water ingress.

Meranti door and window Stiles refer to components used in constructing doors and windows, particularly those made from Meranti timber.

Particle Board Flooring – Green Tongue 3600x900x19mm

Green Tongue Moisture-Resistant Particleboard Flooring by Laminex Trade Essentials offers unbeatable protection from damp or humid conditions. The flooring is made to the highest standards and has an easy-to-use tongue and groove system that provides remarkable strength at unsupported joints.

Features & Benefits

Laminex Trade Essentials – Made in Australia

Plasterboard, often referred to as drywall or gypsum board, is a widely used building material in interior construction. It consists of a core of gypsum sandwiched between two layers of paper or fibreglass. This composition gives plasterboard its characteristic properties of being lightweight, fire-resistant, sound-insulating, and easy to work with.

Plasterboard:

Accessories:

Thermory Interior and Exterior Cladding represent high-quality wood products tailored for both indoor and outdoor applications. Utilizing a specialized thermal modification process, Thermory enhances the natural properties of wood to ensure superior durability, stability, and resistance to environmental factors. Interior cladding options from Thermory are designed to elevate interior spaces with their natural beauty, offering a variety of finishes and profiles to suit different aesthetic preferences. These products not only enhance the visual appeal of walls and ceilings but also contribute to a warm and inviting atmosphere.

On the other hand, Thermory’s exterior cladding solutions are engineered to withstand the rigors of outdoor environments. They are crafted to endure weather elements such as moisture, UV rays, and temperature fluctuations without compromising on appearance or performance over time. This makes them suitable for facades, outdoor walls, and other exterior applications where durability and aesthetic longevity are paramount.

In both interior and exterior applications, Thermory cladding products are chosen not only for their aesthetic charm but also for their sustainability credentials. The thermal modification process not only enhances the wood’s natural beauty but also improves its resistance to decay and insects, contributing to a more sustainable choice compared to untreated wood options.

Timber sheeting typically refers to sheets or panels made from timber or wood materials that are used in construction, particularly for temporary structures or formwork. It’s often used in building projects to create temporary walls, enclosures, or moulds for pouring concrete. Timber sheeting can vary in thickness and size depending on the specific application, and it is commonly made from plywood or oriented strand board (OSB) due to their strength and versatility in construction contexts. These sheets are typically fastened together to form walls or enclosures that can be easily assembled and disassembled as needed on a construction site.

4mm Structural Bracing Ply

9 – 17mm CD Ply Sheets

Formply

16mm Melamine shelving

3-18mm MDF Sheets

Treated pine is an old-school form of screening. It provides additional privacy, but it also adds value to the area of your property where you install it. Pressure-treated pine helps to prolong its life. 4 different lattice profiles depending on your desired aesthetic and level of blocking out. Our 62mm lattice is available in stock and at a highly competitive price. We are also developing a hardwood alternative to lattice for those who want to invest more in a high-quality product.

Treated pine lattice refers to a type of lattice panel made from treated pine timber. Lattice panels are decorative structures commonly used in gardens, landscaping, and outdoor settings for various purposes such as privacy screens, trellises for climbing plants, or decorative accents.

Our new Batten boards are a perfect addition to our range, designed to complement the ADVANCED decking collection. With the same durable and weather-resistant makeup, these battens offer a sleek, modern finish for a variety of outdoor applications. Strong, reliable, and built to last, they provide both style and performance for any project.

For Timber & Metal Subframes

Gap: 5mm

Coverage

HOME: 15m2

ADVANCED 140: 11m2

For Timber & Metal Subframes

Suitable for BAL12.5, BAL 19, BAL29 projects

Gap: 2.5mm

Coverage:

ADVANCED 140 – 15m2

For Timber & Metal Subframes

Suitable for BAL12.5, BAL 19, BAL29 projects

Gap: 3mm

Coverage:

HOME – 15m2

For Timber & Metal Subframes

Gap: 5mm

Coverage:

HOME – 11m2

ADVANCED 140 – 11m2

ADVANCED 200 – 15m2

For Timber & Metal Subframes

Pack Size:

100 pieces

For ADVANCED Boards

Pack Size:

100 pieces

Available for both Timber and Metal subframes with their respective screws.

Available for both Timber and Metal subframes.

ADVANCED

Screw size: 32mm

Material: 304 Stainless Steel

Starter Clip allows you to start your outdoor decking build with a flush look and a sturdy feel.

Driver Bit provides the support needed to get the job done with the right tools.

Our new Batten boards are a perfect addition to our range, designed to complement the ADVANCED decking collection. With the same durable and weather-resistant makeup, these battens offer a sleek, modern finish for a variety of outdoor applications. Strong, reliable, and built to last, they provide both style and performance for any project.

Sizes:

50mmx25mm @ 5.4m

40mmx30mm @ 5.4m

Sizes:

50mmx25mm @ 5.4m

40mmx30mm @ 5.4m

Sizes:

50mmx25mm @ 5.4m

40mmx30mm @ 5.4m

Rex Paine Timber & Hardware has been your local building, renovation and hardware store in Watsona for over 20 years. However, the family business has been going much longer than that with our story beginning back in 1927,

All Rights Reserved | Rex Paine. Copyright © 2025. Design & Marketing by SEO Empire